HEATING ELEMENTS for all types of furnaces

and ovens in raw form as wire, strip or finished form such as coil, strip

corrugated, Rod over Bend (ROB), Radiant Tube, . Both Nickel Based Alloys and Ferrous

based alloys are available in all forms. Elements having melting

temperatures upto 1450 Deg C and continuous furnace running temperature up to

1200 Deg C are available with us. We can supply Heating Elements for all

type of furnaces.

HEATING

ELEMENTS >> INQUIRE NOW

Material of heating Elements

1. Nickel Based Alloys.

Nickel Based Alloys commonly known as NICHROME have the advantages as

anti-oxidization in high-temperature, high strength, non-softened and etc. When

continuously used, it will not transform or elongate permanently. Among them,

Ni/Cr-80/20, with superexcellent comprehensive performance, is the preferred

type for making high quality heating element.

2. Ferrous Based Alloys.

Ferrous Alloys enjoys superior

anti-oxidization, anti-sulfur and anti-cementite. It also has series of

advantages as small specific gravity, high surface load, high resistivity, high

service temperature, long life-span and low price etc. Therefore, it is widely

used in heating elements.

3. Kanthal Heating Elements.

The are alloys made by Kanthal wire and strips of various grades and

temperatures. It also has series of

advantages as small specific gravity, high surface load, high resistivity, high

service temperature, long life-span etc.

4. Silicon Carbide Heating Elements.

Silicon carbide elements comes in rods, U- shape, Bundles and other forms and

are commonly used for high temperatures of about 1200 to 1600 Deg C.

In case your do not know what to use or if you are not sure of specifications

/ designing ask our experts.

Forms of Alloys available

1. Wire - 0.2 mm dia to 7 mm dia

2. Strip - 0.5 to 4 mm Thick and 8 to 40 mm wide

3. Ribbons. 0.08 to 1 mm Thick and 0.2 to 4 mm wide

Send your inquiry / Ask for available standard size from our experts.

Forms of commonly used Heating Elements

1. Coil / Spiral Form.

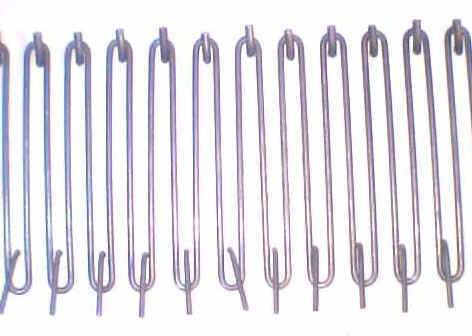

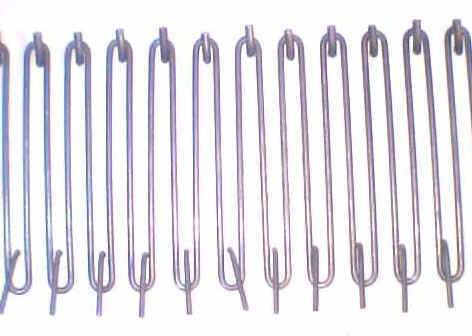

2. Corrugated Strip Element.

3. Rod Over Bend (ROB).

4. Radiant Tube Type.

Send your inquiry / Ask for technical queries from our experts.

IF YOU NEED HEATING

ELEMENTS >> INQUIRE NOW

E-mail us: info@prolific.co.in,

prolificfurnaces@gmail.com